SANITARY CENTRIFUGAL PUMP IN AISI 316 |

||||||||

|

||||||||

General informations |

||||||||

|

||||||||

Advantages |

||||||||

|

||||||||

Applications |

||||||||

|

The sanitary centrifugal pump is widely used in the food, dairy, beverage and pharmaceutical sectors.

Below are some examples:

|

||||||||

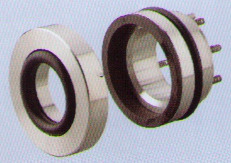

Mechanical Seal |

||||||||

|

||||||||

|

Internal mounting that improves cooling of the seal faces.

External spring not in contact with the product, preventing dirt from remaining in the middle.

Balanced.

Great interchangeability of the seal faces with different materials.

The standard version includes: single mechanical seal, internally mounted, balanced. Alternatively, it is possible to opt for a double flushed mechanical seal: a flushing circuit with water or other clean liquid for cooling or cleaning must be provided (maximum circuit pressure 0.5 bar) |

||||||||

Impelller |

||||||||

|

||||||||

| Open type, and unique piece, built in precision casting which allows for robustness and a perfect finish. High efficiency. Low NPSH, due to its open impeller conditions. Silent pumping. | ||||||||

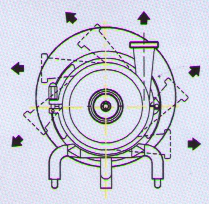

Body |

||||||||

|

||||||||

|

Made of thick sheet metal and cold pressed which guarantees total strength and an accurate finish. Other properties to highlight are:

|

||||||||

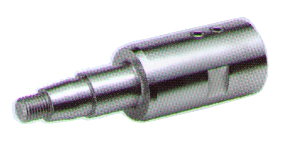

Shaft |

||||||||

|

||||||||

| Its design and perfect finish allows for: interchangeability between different types of motors. No special tools required to change the engine. Minimum eccentricity. Perfect fixing to the crankshaft. Easy assembly and disassembly. | ||||||||

Lantern |

||||||||

| Made of cast stainless steel, which gives greater resistance and avoids vibrations and rust | ||||||||

Closing clamp |

||||||||

| Constructed from cold pressed sheet metal, which gives great solidity, avoiding deformations. Easy to disassemble, it allows for a quick internal inspection or cleaning. | ||||||||

Legs |

||||||||

| The standard pump is supplied with an adjustable stainless steel tripod. | ||||||||